|

PRODUCT MENU

|

| - |

WCCO

Belting |

| - |

Presswheels |

| - |

Kverneland

Hay Spikes |

| - |

Delmhorst

Mosture Meters |

| - |

Roller

Chains, Leaf

Chains & Baler Chains |

| - |

Sprockets,

Platewheels, Taper lock & Reverse Taper |

| - |

Bearings,

Housings & Seals |

| - |

Pulleys

& Belts |

| - |

Gerni

Pressure Cleaners |

| - |

Davey

Pumps |

| - |

Dolmar

Chainsaws |

| - |

Dunlite

Generators |

| - |

Jetstream

|

| - |

Tools

Hand & Air Operated |

| - |

Agparts

Motors & Pumps |

| - |

Fire

Equipment |

| - |

Onga |

| - |

Murray

Mowers |

| - |

Tractor

Parts & Accessories |

| - |

PTO

Driveshafts, Clutches, Universal Joints & Componants |

| - |

Harvest

Belting & Hay Equipment |

| - |

Air

Seeder Hoses, Secondary Heads & Components |

| - |

Ground

Engaging Tools |

| - |

Batteries,

Car, Truck, Tractor & Industrial |

| - |

Britax

Equipment |

| - |

Donaldson

Filtration |

| - |

Hydraulic,

Hoses, Fittings & Rams |

| - |

Transport

Chain & Load Binders |

| - |

Fuel

Pumps, Meters & Grease Guns |

| - |

Engines

& Generators |

| - |

Safety

Equipment |

| - |

Welding

Equipment |

| - |

Clutches |

| - |

Consumables |

| - |

Specials

|

|

| |

|

SWATHER

CANVAS

CONVEYOR

BELTS

BEAN

WINDROWER

BELTS

HARVESTING

TEETH

LACING

HARVEST

HEADER BELTS

BALER

BELTS

COMBINE PICKUP

BELTS

BALE THROWER

BELTS

|

WCCO Belting, Inc

Agricultural

And

Industrial

Belting

Proudly

Distributed by

AGPARTS WAREHOUSE

PH: (08) 9250 2558

12 Runyon Rd Midvale

WESTERN AUSTRALIA 6056

|

Havest Draper

& Pickup Belts

Hay Equipment

The Company was founded in 1954 and was most recently known as the agricultural

belting division of Wahpeton (USA) Canvas Co., Inc.

2004 will mark 50 years

WCCO Belting, Inc. offers a full line of agricultural belting and canvas

products. All products meet or exceed the original equipment manufacturer's

sizes and specifications.

WCCO offers the absolute best quality to keep the user in the field during

the critical harvest season.

Rub-R-Cleat™

Swather Belting.

|

|

Original Equipment

Sizes & Specifications

from every major agricultural equipment manufacturer. WCCO supplies over

90 percent of all swather canvases put on new machines “at the factory”.

The confidence in WCCO workmanship shown by all manufacturers is a direct

result of WCCO’s efforts to maintain product dimensions and standards

for every model. As a result, our canvases meet all the demands of today’s

modern farm machinery.

Only the best materials

are used for WCCO swather canvas products. The carefully developed synthetic

fabrics and compounds used by WCCO provide excellent environmental tolerance

while withstanding highly abrasive conditions. Both are critical to reducing

maintenance and costly downtime. In addition, the fabrics are "reverse

twisted" to ensure the best tracking characteristics.

Unsurpassed Quality

keeps you in the field during the critical haying and harvesting seasons.

Prior to shipment, each canvas produced by WCCO is inspected to assure

compliance with strict quality standards. Ours is an ISO-9001 Quality

Certified facility.

Most Durable by design.

All rubber cleats on WCCO’s Rub-R-Cleat™ canvases are vulcanized

under heat and pressure to become an integral part of the finished belt.

The edges of the belts are subject to heavy stress and are double reinforced

to extend the life of the canvas. The belts are also reinforced with a

double strip in the center. Our standard cured rubberized fabric will

significantly outlast conventional canvases.

State-Of-The-Art Design

ensures you that you’ll receive only the best swather canvas. WCCO

is committed to being the industry’s engineering leader. We provide

fiberglass reinforcement rods in all Rub-R Cleat™ canvases. The rods

are shaped to provide enhanced rigidity without sharp edges that can increase

"wear" in high stress areas. In addition, our Econo-Cleat™

Wood and Poly slat models have more staples and rivets per cleat, which

reduces stalk and weed pick up.

Most Reliable construction.

What makes WCCO canvases durable also makes them reliable. Impregnated

rubber cleats, vulcanized rubber-coated fabrics, Fiberglas reinforced

rods, materials that won’t shrink, rot, or mildew, poly cleats and

reinforced edges all keep WCCO products running longer.

Economical to own.

When considering the superior materials, quality workmanship and state-of-the-art

designs, your best values are WCCO swather canvases.

Our Research and Development Continues

to provide space-age materials to reduce the weight of our belts, the

power required to drive the belts and increase strength and life of the

belts at the same time.

Combine Pickup &

Harvest

Header Belts

Rubberized Belting

With Or Without

Harvesting Teeth

|

|

Original Equipment Sizes & Specifications

from every major agricultural equipment manufacturer. The confidence

in WCCO workmanship shown by all manufacturers is accomplished because

of WCCO’s efforts to maintain product dimensions and standards

for every model. As a result, our belts and teeth meet all the demands

of today’s modern harvesting equipment.

Materials used for WCCO combine pickup belts and teeth.

The unique fabrics and components used by WCCO provide excellent environmental

resistance while withstanding highly abrasive conditions. Both are critical

to reducing maintenance and costly downtime.

Unsurpassed Quality

keeps you in the field during the critical harvesting season. Prior

to shipment, each pickup belt produced by WCCO is hand inspected to

assure compliance with strict quality standards.

Most Durable by design.

All WCCO combine pickup fabrics are rubber vulcanized under extreme

heat and pressure. Our standard two-ply rubberized fabric, with a specially

designed

angled lacing, is engineered for optimum tracking and excellent dimensional

retention.

State-Of-The-Art Design

ensures that you’ll receive only the best combine pickup belts

and teeth. WCCO is committed to being the industry’s engineering

leader, and WCCO innovation now brings you a combine pickup belt with

a “double prong” tooth design. The WCCO tooth contains a special

plastic compound specifically designed to withstand even the roughest

field conditions. The unique flex construction of the teeth, along with

the most efficient angle of pickup, puts the WCCO combine pickup belts

ahead of any other pickup available today.

Most Reliable construction.

What makes WCCO pick-up belts durable also makes them reliable. Vulcanized

rubbercoated fabrics, “double prong” pickup teeth, and materials

that won’t shrink, rot, or mildew all keep WCCO pickup belts running

longer.

Economical to own.

When considering the superior materials, quality workmanship and state-of-the-art

designs, your best values are WCCO combine pickup products.

Swather Belt Installation

Please Read

A few minutes of your time can prevent premature belt failure

and costly down time.

Preparation –

Before

1. Check all bearings for movement without drag or noise. Lubricate

or replace as required.

2. Check for bent or broken rollers and replace as required.

Free all rollers of rust and foreign material buildup.

3. Eliminate catch points, weld splatters and sharp metal edges.

Maintenance –

After

1. Drapers should be REMOVED when the machine is not to be used,

or if it is exposed to weather for an EXTENDED period of time. Roller

rust and deterioration caused by decaying materials, accelerated by

wet conditions, can result in premature belt failure.

2. Store drapers in a protected, dry place.

3. On swathers using two belts of equal size, ALTERNATE belts

PERIODICALLY to even wear and extend belt life.

4. Before re-installing belt for the next season, EXAMINE fastener

bar connectors closely. REPLACE bent or broken connectors immediately

to prevent belt damage.

5. Remember WCCO Swather/Windrower Belts are specially designed

for this application. Special materials and quality craftsmanship make

WCCO Belts excellent replacement products, that meet or exceed O.E.M.

requirement

Installation

1. You can operate your WCCO Swather Belt in either direction.

However, install the HEADS of the connector bolts so they are facing

the direction most frequently operated.

2. Remove excess material on the flap. To prevent noisy slapping

effect during operation, trim tail end flaps to ¼ inch after

fastener bar has been tightened.

3. Belts will tend to creep toward the slack side of the roller.

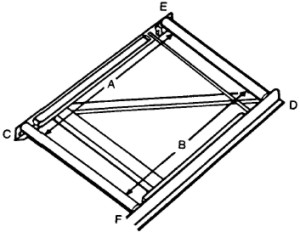

If distance “A” is less than distance “B”, then

the belt will tend to run toward the high side of the roller carriage.

If distance “A” is greater than “B”, then the belt

will run toward the low side of the roller carriage.

4. When adjusting the roller carriage, always keep the rollers

parallel with each other. For best results, measure roller ends diagonally

across roller carriage making sure the distance from points “C”

to “D” is EQUAL with he distance from points “E”

to “F”.

Baler and Industrial

Conveyor Belting

2 or 3 Ply.

|

- 2 & 3 ply

Baler Belting

- Cut-To-Length

- Bulk Roll |

olls

Original Equipment Sizes & Specifications from every major agricultural

equipment manufacturer.

The confidence in WCCO workmanship shown by all manufacturers exists

because of WCCO’s efforts to maintain product dimensions and standards

for every

model. As a result, our belts meet all the demands of today’s modern

farm machinery. Materials used for WCCO baler belt products. The unique

fabrics and

compounds used by WCCO provide excellent environmental resistance while

withstanding highly abrasive conditions. Both are critical to reducing

maintenance and costly downtime.

Unsurpassed Quality keeps you in the field during the critical haying

season.

Prior to shipment, each belt produced by WCCO is hand inspected to assure

compliance with strict quality standards.

Most Durable by design.

All special textures on WCCO’s baler belt models are vulcanized

under heat and pressure to become an integral part of the finished belt.

That is essential in order to withstand the extreme flexing which is

common on large round balers. Our standard two- or three-ply rubberized

fabric, with a specially designed rectangular-angled lacing, is engineered

for optimum tracking and excellent dimensional retention.

State-Of-The-Art Design ensures you that you’ll receive only the

best baler belts.

WCCO is committed to being the industry’s engineering leader, and

our latest technological advancement gives you a full line of belting

textures, which all meet manufacturers’ specifications. Those textures

are mandatory to ensure proper operation of the various balers in the

market today. WCCO offers Rough Top Herringbone, Mini-Rough Top, Texture

Top, Diamond Top, Continuous Chevron, plus more. Don’t cut yourself

short by putting a belt on your machine that’s not designed for

maximum productivity.

Most Reliable construction.

What makes WCCO baler belts durable also makes them reliable. Impregnated

rubber patterns, vulcanized rubber-coated fabrics, and materials that

won’t stretch, shrink, rot, or mildew all keep WCCO baler products

running longer.

Economical to own.

When considering the superior materials, quality workmanship and state-of-the-art

designs, your best values are WCCO baler belt products.

- Endless Baler Belting

- Cut-To-Length

- Bulk Rolls

Round

Baler Belt Installation

PLEASE READ

A few minutes of your time can prevent premature belt failure

and costly down time.

Preparation – Before

1. Always use the same ply construction for all belts. Two-ply

and three-ply constructions do not react in the same manner under tension.

Use of different ply constructions will create an unequal load situation

and the baler will not perform properly.

2. Check all bearings for movement without drag or noise. Lubricate

or replace as required.

3. Check for bent or broken rollers and replace as required.

Free all rollers of rust and foreign material buildup.

4. Eliminate catch points, weld splatters and sharp metal edges.

5. Replace all worn belts at the same time.

6. Resize all belts, new and old, to equal lengths for maximum

load distribution.

(NOTE: Resize all belts between

each baling season.)

Maintenance – After

1. Take up roller adjustment to recommended tension. (Important:

Check your baler’s operating manual for proper tension adjustment.

NOTE: It is especially important

to leave the recommended slack in the belts on Vicon, McKee, New Idea

and corresponding Case IH models. A belt adjusted too tight will have

a shorter service life.)

2. Check your belts, belt lacing and pin occasionally during

use. Make repairs or replacements as required. (Note:

The lacing and connecting pin are your belts’ weakest points. Proper

maintenance is critical to your baler’s overall performance.)

3. Resize all belts and replace as necessary between baling seasons.

Check your baler thoroughly before starting your next baling season.

4. Remember, WCCO Baler Belts are specially designed for large

round balers. Special materials and quality craftsmanship make WCCO

Baler Belts excellent replacement products that meet or exceed O.E.M.

requirement.

Installation - Upper Belts

1. Install belt following “Direction Of Travel” arrow.

(End with 45 degree corners and the least number of hooks is the trailing

end. End with square-cut corners is the leading end.)

2. After threading a belt through the machine, pull ends together.

Insert connecting pin through the lacing hooks making sure the hooks

on both end alternate. (Leading end should have hooks on both outside

edges.)

3. After inserting the connecting pin completely, bend approximately

¼ inch of the straight end at a 90 degree angle to match the

other end.

Installation - Lower Platform Aprons

1. Clean V-guide slot on pulleys. (Note: International Harvester

models do not have V-guides.)

2. [Follow steps 1& 2 from Upper Belts instructions above.]

3. If Clipper Lacing is used, insert leader wire attached to

cable, through hooks. Do not jerk on leader wire or it will come off.

After cable is in place, remove leader wire, attach retaining nut and

crimp it. If Minet Lacing is used, install pin and bend approximately

¼ inch of straight end at a 90 degree angle.

4. Run baler momentarily to check for proper tracking, adjust

as necessary.

NOTE: Belts which are all replaced

as a set, will generally fit better and last longer.

Endless Baler Belt Installation

Tip:

After installing the new belts, decrease the belt tension to about 60%

to 70% of the normal baling tension and run the PTO slow (less than half

normal speed). Watch the belts for tracking so they don't run up against

any belt guides. This will probably take some roller adjustments on the

baler. Adjust the rollers according to the Baler Owners Manual. Slowly

increase the PTO speed while watching the belts for tracking. Slowly increase

the belt tension to no more than 75% of normal baling tension. If the

belts are running proper, you can go to the field for baling. Start baling

at a reduced throttle speed to insure proper installation and tracking

of the new belts. Do not increase the belt tension for increased bale

density until you have ran at least 25 bales. This will allow the belts

to break in and conform to your baler. Continue to monitor your belts

daily and make adjustments when necessary.

Belt Lacing and Tools.

|

|

|

|

Agparts stock

Clipper vice lacer 7" and 10" tools for easy in-field

service.Titan and Mato vice lacer tools available as well.

|

Various baler

belts use different fasteners for the splice. Note that different

O.E.M.’s have different specifications. Agparts keep a comprehensive

range of Clipper, Titan Goro and Mato joiners and joiner wires.

|

Smartlocks are

a great way to protect the joiner ends from pulling out. Easy

to install with Clipper type joiners.

|

Field

Service Guide for Belting

TRACKING PROBLEMS

Belt runs to one side along given

point on machine.

1. Idler or idlers that immediately precede trouble point are

not at right angles to longitudinal axis of Advance the end of the idler

to which the belt has shifted in the direction of belt travel. Check

for belt end squareness to belt centerline.

2. Frozen and sticking idlers Lubrication poor, improve general

maintenance.

3. Frame of conveyor crooked or idler stand not centered.Determine

extent of misalignment, then square.

4. Material building up on idlers. Check installation of scrapers,

or other cleaning devices. Improve general maintenance.

A single section of the belt tends

to run to one side along the machine.

1. Crooked splice. Belt needs re-splicing with ends squared with

belt centerline.

2. Crooked end of belt at fasteners, or fasteners not joined

squarely. Belt should be re-spliced, if possible, using new fasteners.

3. Bow in belt. New belt may straighten out as it becomes broken

in.

Wandering Belt

1. Belt too heavy or stiff for drive rollers. Replace with a

more flexible belt.

2. Poor loading or off-center loading. Change loading procedures.

WEARING PROBLEMS

Damaging wear on drive roller side

of belt.

1. Drive roller is slipping. Increase take-up, lag drive or increase

arc of contact on drive roller with snubber oil.

2. Loading end of belt has buildup of material which is being

ground between belt and drive roller. Improve belt loading procedures.

Install plows or scrapers in front of drive roller on return run. If

leakage through fasteners, use belt with flap or vulcanized splice.

3. Idlers are sticking. Increase maintenance and lubrication.

4. bolt heads protruding above lagging. Replace worn lagging

on pulley. Tighten bolts. Cement lagging to pulley.

Excessive edge wear.

1. Folding of belt edge on edge guard or frame. Consider using more

stable construction. Provide more clearance. Smooth any rough areas

on

2. Side loading. Load in direction of belt travel.

3. Buildup of material on drive roller. Install scrapers to eliminate

buildup from pushing belt against frame.

Top Cover Wear

1. Return idlers dirty, frozen or misaligned. Clean belt; clean

and lubricate idlers .. Improve maintenance. May need cleaning device

installed. Check alignment of return idlers.

2. Poor loading conditions. Correct to feed onto center of belt

in same direction as belt runs. Material falling down from delivery

chute should be at about same speed as conveyor belt.

3. Sags in belt letting load shift as it passes over idlers.

Increase belt tension and/or reduce idler spacing.

Top cover grooved and gouged.

1. Skirt boards are pressing against belt. Skirt boards are too

hard. Redesign skirt board to permit material to work out, not in. Change

to softer material for skirt board. Do not use reinforced rubber for

skirt boards.

2. Space between belt and skirt seals is too great. Adjust to

minimum clearance and angle to belt to allow material to work itself

out.

3. Material jammed at chute. Redesign chute.

4. Metal side of chute or skirts too close to belt. Adjust so

gap between metal and belt increases in direction of travel to avoid

jamming.

BREAKING

PROBLEMS

Breaks in belt parallel to belt edge

or star breaks in belts.

1 Heavy lumps falling on belt or falling from too great a height. Reduce

impact of material by redesigning loading area.

2 Material lodged between belt and pulley or stuck to back. Return run

should have scrapers ahead of tail pulley. Check loading design to reduce

material

Breaks in belt parallel to belt edge or star breaks in belts.

Belt fasteners too large for drive roller size being used. Replace with

manufacturer's recommended fasteners.

Transverse breaks at belt edge.

1. Folding up of belt edges. Improve tracking. Increase lateral

clearance. Redesign of belt construction may be required.

2. Belt is mildewed. Use belt with polyester or nylon fabrics

and mildew inhibitor in rubber compounds. All WCCO belting have synthetic

fabrics and contain mildew inhibitors.

3. Idler next to drive roller is located too high. Reposition

final idler in line with drive roller and previous idler.

Fasteners pulling out, tearing belt.

1. Fasteners wrong size or not tight. Replace fasteners and inspect

regularly. Consider fasteners with longer reach.

2. Belt too tight. Correct belt tension.

Fasteners let go.

1. Fasteners not clinched tightly. Replace fasteners and clinch

tightly.

2. Fasteners wrong size. Replace with proper size fasteners.

3. Fasteners too weak. Replace with higher strength fasteners.

Fasteners on edge pull through belt.

1. Fasteners too close to edge. Check fastener to edge distance,

leave 1/4 inch between last fastener and belt edge.

2. Pin improperly installed. Replace pin.

STRETCHING AND SHRINKING

PROBLEMS

Stretching

1. Belt too tight. Reduce take-up tension.

2. Belt not heavy enough for desired application. Switch to a

higher grade belt.

3. Frozen idlers or buildup of material on drive rollers and

idlers. Improve maintenance and clean-up. Lube or replace frozen idlers.

Shrinking

1. Bad edge on belt due to rubbing. Improve alignment of idlers,

drive rollers and tracking of belt. Consider narrower belt.

2. Damage by abrasives, chemicals, mildew, acid heat and oil.

Specify belt with proper resistance for material being handled. Check

maintenance procedures.

3. Improper adhesion.

Cracking covers

1. Abrasion, chemical, acid or rot damage. Specify belt with

proper rubber compounds for material being handled.

2. Belt too tight. East tension on belt and use some type of

compensating take-up. Consider lagging drive and using snub oil.

|

|